Dr. Denis Cormier: Pioneering the Future of Additive Manufacturing

A natural curiosity for emerging technologies has guided Dr. Denis Cormier throughout his career, driving him to use 3D printing as a powerful force in modern manufacturing. From his early fascination with the technology in the 1990s to his current role leading impactful research collaborations at Rochester Institute of Technology (RIT), Dr. Cormier has spent decades advancing additive manufacturing and shaping the future of American industry.

A Journey into 3D Printing

Dr. Cormier’s fascination with 3D printing began in 1993, just as the field was entering its early stages. By 2003, he was exploring metal 3D printing and forging relationships with aerospace companies intent on pushing the limits of manufacturing innovation. After earning both a master’s degree and Ph.D. in artificial intelligence from NC State University, Dr. Cormier channeled his technical expertise in computer vision and machine learning into practical applications in manufacturing.

Dr. Cormier served on the faculty at NC State for 15 years before joining RIT, where he has spent the last 16 years. Currently, he directs RIT’s Additive Manufacturing and Multifunctional Printing (AMPrint) Center, a hub for breakthrough research, collaboration, and workforce development opportunities.

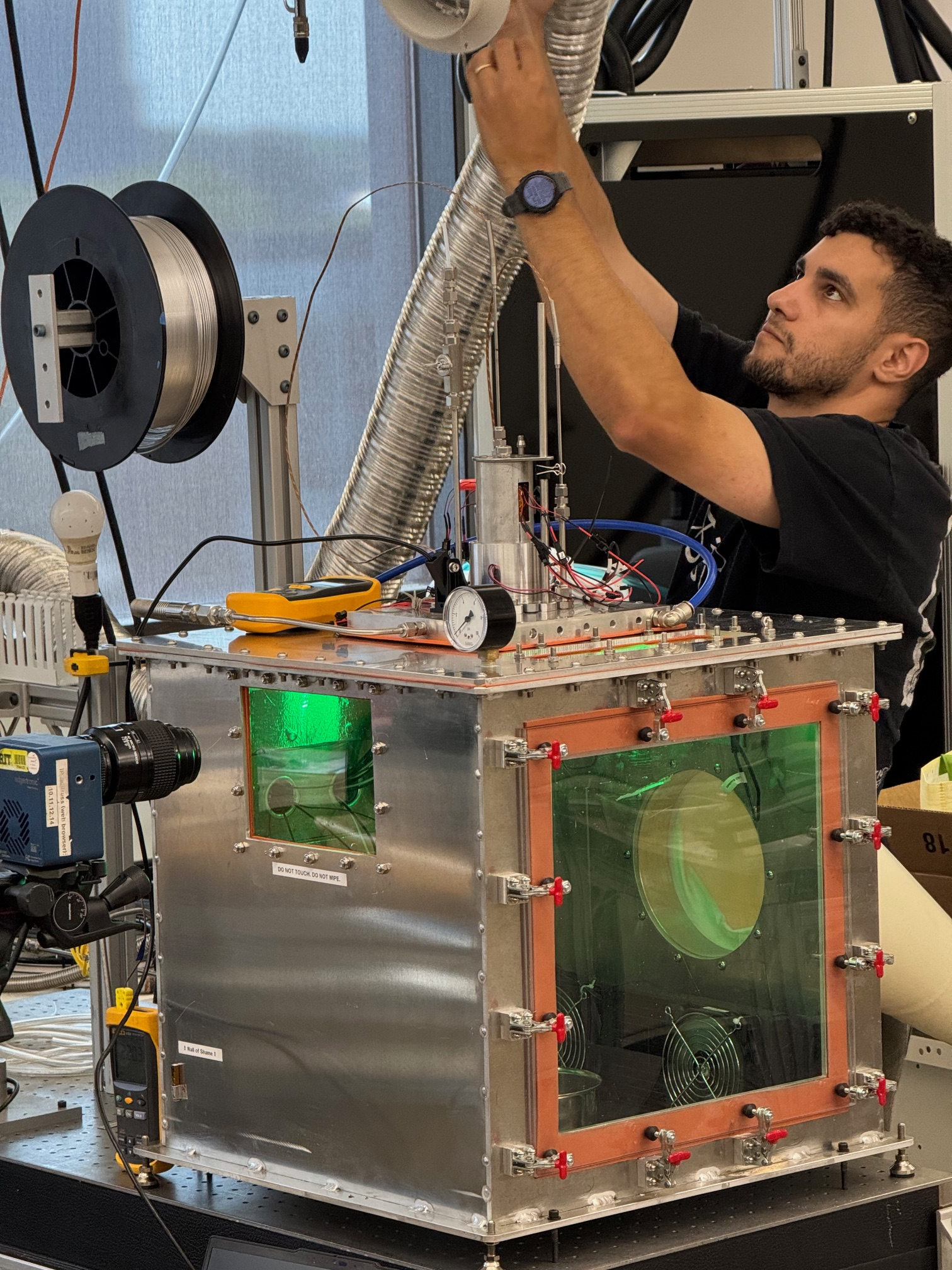

A student researcher stands with the world’s first multi-nozzle molten metal inkjet printer.

Research at the Leading Edge

The AMPrint Center operates at the nexus of process, material, and application, backed by both state and federal support. Approximately half of its funding comes from New York State, with the other half provided by federal agencies and industry partners — a model that ensures taxpayer investment directly benefits the state and its industries.

Currently, Dr. Cormier’s team manages 7–10 federally funded research projects, in partnership with private companies. These projects focus on advanced manufacturing technology, with applications ranging from lightweight drones to defense production.

One notable collaboration involves working with Impossible Objects to create carbon-fiber composite printed parts. Combining lightweight strength with blindingly fast production speeds, this technology has immense potential to scale up rapid manufacturing capabilities.

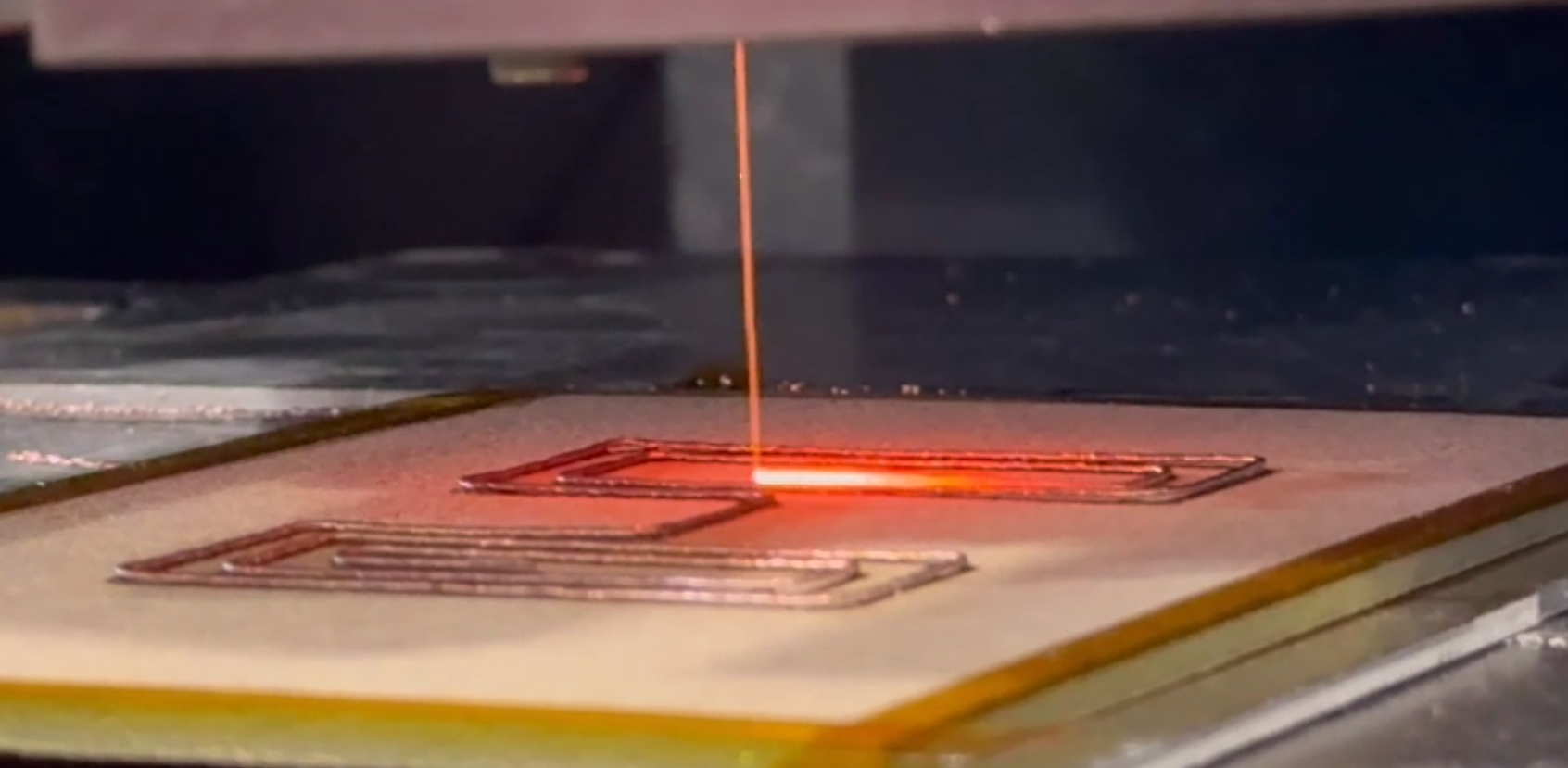

Earlier this year, Dr. Cormier and his collaborators at Virginia Tech and New Mexico State University received a $3 million NSF Future Manufacturing Research Program grant. Their groundbreaking project explores a new additive process akin to inkjet printing — but with molten metal. This approach promises to overcome longstanding limitations in metal 3D printing, delivering faster, cheaper, and more efficient hardware that could open the door

to new industrial and defense applications.

Why Federal Investment Matters

Dr. Cormier is clear about the importance of federal funding in pushing America’s manufacturing prowess and innovation forward.

“Next-generation technologies carry massive risk,” he notes, “and government agencies have a responsibility to help move the needle.”

At a time when private companies are often reluctant to invest in R&D that doesn’t return immediate results, federal support ensures that high-risk, high-reward research can continue. Without it, innovation could stall at precisely the moment when progress is needed most.

Building the Workforce of the Future

A central mission of the AMPrint Center is workforce development. The center houses undergraduate, graduate, and Ph.D. researchers, while also employing six full-time technical staff who work closely with both students and industry partners. At any given time, the center supports 10 to 15 Ph.D. students through a variety of grants. This hands-on training ensures the next generation of engineers, scientists, and innovators is prepared to lead in the rapidly evolving field of advanced manufacturing.

Shaping Tomorrow’s Manufacturing Landscape

From supporting small and mid-sized businesses in accessing competitive federal funding opportunities to leading collaborative research that reimagines how metals and composites can be printed, Dr. Cormier’s work extends well beyond the lab. He is helping shape the trajectory of U.S. manufacturing – ensuring that innovation, workforce readiness, and industry competitiveness remain at the forefront.

This year, The Science Coalition (TSC) benefitted enormously from Dr. Cormier’s expertise. He designed and manufactured a new award for TSC’s Champion of Science program using 3D-printing technologies. You can learn more about the Champion of Science program here.

2025 Champions of Science Award.

Dr. Denis Cormier represents the ingenuity and leadership that define the nation’s scientific research and manufacturing future – all powered by federal investments.

Inkjet printing a molten copper circuit pattern with precise control of droplet placement.